Pulley Puller

HIGH QUALITY PRECISE MANUFACTURER &SUPPLIER

Leading Innovator in High-Quality Pulley Pullers for Diverse Applications

We have established ourselves as a leading manufacturer and supplier of pulley pullers, renowned for our commitment to quality, innovation, and customer satisfaction. With a state-of-the-art production facility and a team of highly skilled engineers, our company has grown to become a significant player in the industry. We leverage cutting-edge technology and rigorous quality control processes to ensure our products meet the highest standards of performance and durability.

Our pulley pullers are designed with unique features such as adjustable arms, interchangeable jaws, and hydraulic assist, making them suitable for a wide range of applications, including automotive repairs, industrial machinery maintenance, and agricultural equipment servicing. These tools are built from high-grade materials to withstand heavy use, ensuring longevity and reliability. The compact design and non-slip grips enhance user safety and ease of operation, even in confined spaces.

We prides itself on its expertise and influence in the pulley puller market. We have earned a reputation for delivering products that not only meet but exceed customer expectations. Our dedicated R&D team continually innovates to introduce advanced solutions that address the evolving needs of our clients.

Our service philosophy centers on exceptional customer support and after-sales service. We offer comprehensive warranties and responsive technical assistance to ensure our customers can rely on our products for their critical tasks. We is committed to continuous improvement and innovation, striving to remain at the forefront of the pulley puller industry.

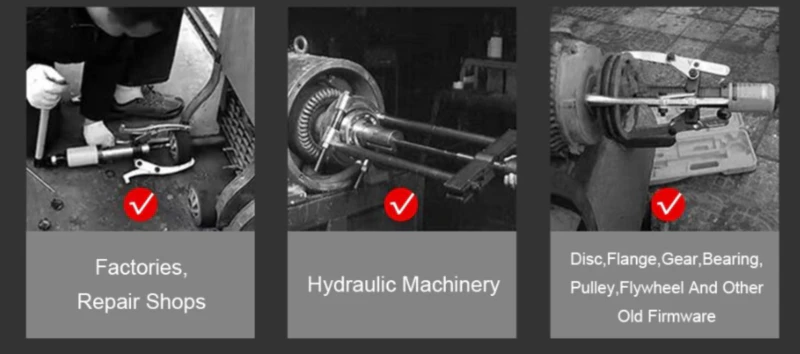

Pulley puller application industry

Automotive Industry

Applications: Removing and installing pulleys in engines, alternators, and belt-driven systems.

Industrial Machinery

Applications: Maintenance and servicing of industrial equipment such as conveyors, compressors, and pumps.

Marine Industry

Applications: Servicing marine engines and related equipment.

Agricultural Sector

Applications: Repair and maintenance of farm machinery, including tractors, harvesters, and irrigation systems.

HVAC Systems

Applications: Maintenance of heating, ventilation, and air conditioning systems.

Construction Equipment

Applications: Servicing and maintaining construction machinery such as excavators, bulldozers, and cranes.

What is a Pulley Puller?

A pulley puller is a specialized tool designed to remove and install pulleys on various types of machinery and equipment efficiently and safely. Pulleys are integral components in many mechanical systems, serving to transfer rotational motion and power through belts. Over time, these pulleys may need to be replaced or adjusted, and that’s where a pulley puller becomes essential.

Pulley pullers typically consist of adjustable arms, interchangeable jaws, and sometimes a hydraulic assist mechanism. The adjustable arms and jaws allow the tool to fit a wide range of pulley sizes and shapes, making it versatile for different applications. The hydraulic assist provides additional force, which is particularly useful for removing stubborn or heavy-duty pulleys with minimal manual effort.

Different Types of Pulley Pullers

Two-Jaw Puller

Description: Features two adjustable jaws that grip the pulley from opposite sides.

Three-Jaw Puller

Description: Equipped with three adjustable jaws for a more secure and balanced grip.

Hydraulic Puller

Description: Hydraulic force is used to apply pressure and remove pulleys.

Manual Screw Puller

Description: Operates by turning a central screw to apply pressure.

Features of pulley puller

Adjustable Arms

Description: Pulley pullers often come with arms that can be adjusted to fit various pulley sizes and shapes.

Advantage: This feature allows the tool to be versatile, accommodating a wide range of applications and pulley configurations.

Durable Construction

Description: Typically made from high-grade materials such as hardened steel.

Advantage: The robust construction ensures the tool can withstand significant force and frequent use, providing long-term reliability.

Interchangeable Jaws

Description: Many pulley pullers include jaws that can be swapped out depending on the type and size of the pulley.

Advantage: The ability to change jaws enhances the tool’s adaptability and extends its usability across different tasks.

Compact Design

Description: Pulley pullers are often designed to be compact and lightweight.

Advantage: The compact design makes it easy to handle and operate the tool in confined spaces, such as engine compartments.

Hydraulic Assist

Description: Some pulley pullers are equipped with a hydraulic mechanism that applies additional force.

Advantage: The hydraulic assist reduces the manual effort required and makes it easier to remove stubborn or heavy-duty pulleys.

Non-Slip Grip

Description: Handles of pulley pullers often feature non-slip grips.

Advantage: This ensures a secure hold during operation, enhancing safety and ease of use.

Pulley Puller for sale

-

10 Ton 2/3 Jaws Optional Anti Skid Hydraulic Gear Puller for Pipeline Connection

-

2/3 Jaws Optional 5 Ton Inner and Outer Diameter Anti-Skid Hydraulic Puller

-

Inner and Outer Diameter Anti Skid 20 Ton 30-350 mm Stroke 2/3 Jaws Optional Hydraulic Puller

-

OEM 2/3 Jaws 50 Tons Inner and Outer Diameter Anti-Skid Hydraulic Puller

-

Reinforced 3 Jaw Flywheel Puller Tools 10/12/20/30 Ton Pulley Bearing Puller

-

Snap on Axle Bearing Puller Flange Tool Large Combination Puller Set for Sale

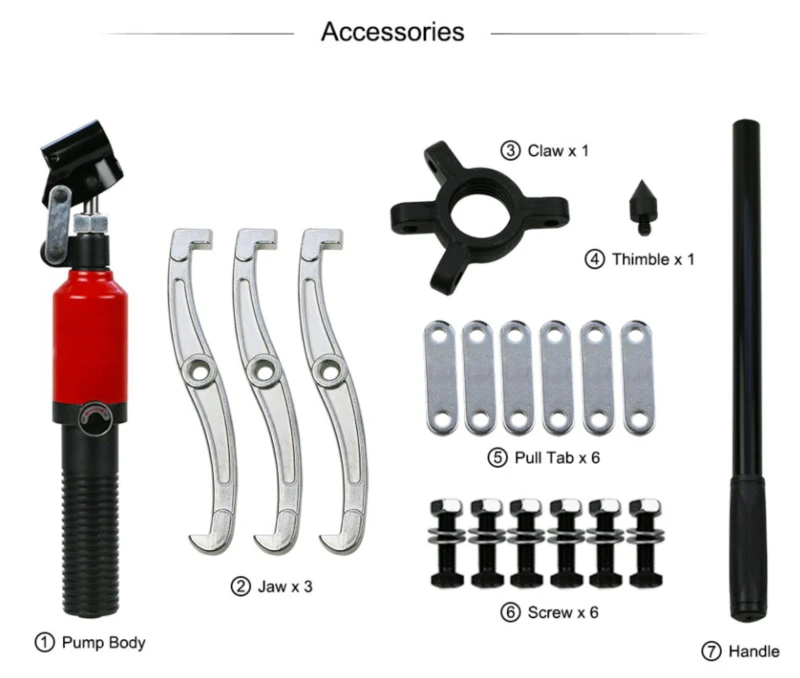

Accessories for pulley puller

1. Interchangeable Jaws

Description: Different sets of jaws that can be swapped out to fit various pulley sizes and shapes.

Advantage: Enhances the versatility of the pulley puller, allowing it to accommodate a wider range of pulleys.

2. Extension Arms

Description: Additional arms that can be attached to the puller to extend its reach.

Advantage: Useful for accessing pulleys located in hard-to-reach areas or for handling larger pulleys.

3. Hydraulic Pumps

Description: Hydraulic pumps that can be connected to hydraulic pulley pullers.

Advantage: Provides the necessary hydraulic pressure to assist in the removal of heavy-duty pulleys with minimal manual effort.

4. Puller Bolts

Description: Various sizes of bolts that can be used to secure the puller to the pulley.

Advantage: Ensures a secure and stable attachment, which is critical for safe and effective pulley removal.

5. Spacers and Washers

Description: Spacers and washers that can be used to adjust the position and fit of the puller.

Advantage: Allows for precise alignment and ensures even force distribution during the removal process.

6. Carrying Case

Description: A durable case for storing the pulley puller and its accessories.

Advantage: Keeps all components organized and protected, making it easy to transport and store the tool.

7. Puller Plates

Description: Plates that can be attached to the puller for additional support and stability.

Advantage: Provides extra leverage and prevents the puller from slipping during operation.

8. T-Handles and Wrenches

Description: T-handles or wrenches that can be used to operate the puller.

Advantage: Provides a comfortable grip and precise control when applying force.

9. Bearing Separators

Description: Tools that can be used in conjunction with pulley pullers to separate bearings from pulleys.

Advantage: Facilitates the removal of bearings that are tightly fitted to pulleys, ensuring a smooth and damage-free process.

10. Adapters

Description: Various adapters that can be used to modify the puller for different applications.

Advantage: Increases the versatility of the puller, allowing it to be used with different types of machinery and pulleys.

11. Guide Pins

Description: Pins that help align the puller with the pulley shaft.

Advantage: Ensures accurate alignment and prevents misalignment during the removal process.

12. Safety Shields

Description: Shields that protect the user from debris or parts that might fly off during the pulley removal process.

Advantage: Enhances safety by preventing injuries caused by flying debris.

How to Determine the Right Pulley Puller Size for Your Needs?

1. Determine Pulley Size and Type

Measure Pulley Diameter: Use a caliper or tape measure to measure the diameter of the pulley you need to remove or install.

Determine Pulley Type: Determine if the pulley is a V-belt, flat belt, timing belt, or another type. This helps select a puller with the correct jaw design.

2. Check Pulley Accessibility

Assess Space Around the Pulley: Make sure there is enough clearance around the pulley for the pulley arm and jaws to fit and operate. This is especially important in tight spaces, such as an engine compartment.

3. Assess Shaft Size

Measure Shaft Diameter: Determine the diameter of the shaft you are removing the pulley from. This helps select a puller with a center screw or hydraulic cylinder that can accommodate the shaft size.

4. Consider Pulley Material and Condition

Material Strength: If the pulley is made of a delicate material, select a puller that applies force evenly to avoid damage.

Pulley Condition: For rusted or stuck pulleys, a hydraulic puller may be more effective because it applies more force.

5. Determine the amount of force required

Manual vs. hydraulic: Manual pullers are good for small to medium-sized pulleys that don’t require excessive force. Hydraulic pullers are better suited for large or stubborn pulleys that require more force to remove.

6. Choose the right jaw configuration

Two-jaw vs. three-jaw: Two-jaw pullers are ideal for small, easily accessible pulleys. Three-jaw pullers offer more stability and are better suited for larger or more firmly mounted pulleys.

7. Look for adjustable features

Adjustable arms and jaws: Make sure the puller has adjustable arms and interchangeable jaws to accommodate a variety of pulley sizes and shapes. This increases versatility and allows you to use the puller for different applications.

8. Read manufacturer specifications

Weight capacity: Check the puller’s weight capacity to ensure it can handle the weight of the pulley.

Maximum reach and extension: Verify the puller arm’s maximum reach and extension to ensure it’s the right size for the pulley.

9. Consider the application environment

Industry requirements: Different industries may have specific requirements for tools. Make sure the puller meets the standards and specifications for your industry, whether it’s automotive, industrial, marine or agricultural.

10. Consult an Expert

Seek professional advice: If you’re unsure, consult a professional mechanic or tool expert. They can provide advice based on their experience and your specific needs.

Blog

Maintain your pulley puller to extend its life and improve its performance

1. Regular Cleaning

After Each Use: Clean the pulley puller after every use to remove dirt, grease, and debris. Use a soft cloth and a mild solvent to wipe down the tool.

Deep Cleaning: Periodically perform a thorough cleaning, especially if the tool has been used in harsh environments. Disassemble parts if necessary and clean each component individually.

2. Lubrication

Moving Parts: Apply a light machine oil or appropriate lubricant to all moving parts, such as the central screw, adjustable arms, and jaws. This reduces friction and prevents rust.

Hydraulic Components: If you have a hydraulic puller, ensure the hydraulic system is well-lubricated and check for any leaks.

3. Inspection for Wear and Damage

Visual Inspection: Regularly inspect the puller for signs of wear, cracks, or damage. Pay particular attention to the jaws, arms, and central screw.

Functional Check: Ensure that all parts move smoothly and that the puller operates correctly without any unusual resistance or noise.

4. Tightening and Adjustment

Check Fasteners: Periodically check all screws, nuts, and bolts to ensure they are tight and secure. Loose components can affect the tool’s performance and safety.

Adjustable Arms and Jaws: Verify that the adjustable parts are functioning correctly and can be securely locked in place.

5. Storage

Dry Environment: Store the pulley puller in a dry, clean place to prevent rust and corrosion. Avoid damp or humid environments.

Protective Case: If available, use a protective case to store the puller and its accessories. This helps keep the tool organized and protected from dust and impact.

6. Preventive Maintenance

Scheduled Maintenance: Set up a regular maintenance schedule based on the frequency of use. More frequent use may require more frequent maintenance.

Replace Worn Parts: Replace any worn or damaged parts promptly to ensure the tool remains in optimal working condition.

7. Proper Use

Correct Application: Always use the pulley puller within its specified capacity and for its intended purpose. Overloading or misuse can lead to damage and reduce the tool’s lifespan.

Follow Instructions: Adhere to the manufacturer’s instructions and guidelines for use and maintenance.

8. Hydraulic System Maintenance

Fluid Levels: Regularly check and maintain the hydraulic fluid levels if you have a hydraulic puller. Use the recommended type of hydraulic fluid.

Leak Checks: Inspect the hydraulic system for any signs of leaks and address them immediately to prevent further damage.

9. Protective Coatings

Anti-Rust Coating: Apply a rust-preventive spray or coating to metal parts to protect them from corrosion.

Protective Wraps: Use protective wraps or covers for additional protection during storage or transport.

Why choose our company?

1. High-quality products: Our company is committed to providing the highest-quality pulley puller. Our products are precision-engineered and manufactured using advanced materials to ensure durability, reliability, and consistent performance.

2. Comprehensive Service: We pride ourselves on providing excellent customer service. Our professional team is ready to answer your questions, provide technical support, and provide solutions tailored to your needs.

3. Competitive Prices: Our company offers competitive prices without compromising quality. We believe in creating value for our customers and work hard to ensure our products fit every budget.

4. Excellent after-sales support: We know a product is only as good as the support you receive after purchasing it. Our company provides comprehensive after-sales services, including timely repair, replacement, and maintenance, ensuring that your pulley puller is in optimal condition for a more extended period.

5. Rich product range: Our company provides a variety of pulley puller shafts to meet different applications and requirements. We can provide you with the right product.